- The benefits of laser cleaning for removing contaminants from glass surfaces

- Comparison of laser cleaning with traditional cleaning methods for glass surfaces

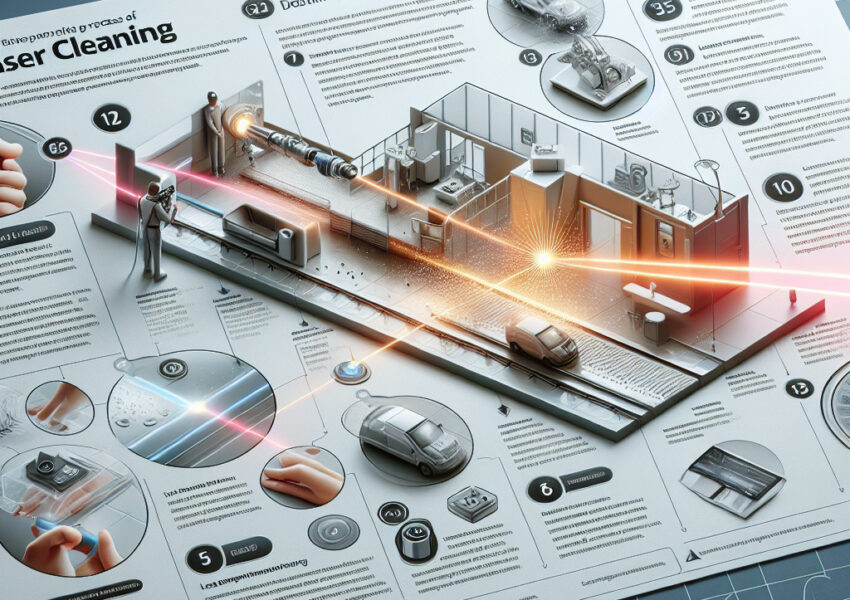

- The science behind laser cleaning and how it works on glass surfaces

- Case studies of successful applications of laser cleaning on glass surfaces

- Safety considerations when using laser cleaning for glass surfaces

The benefits of laser cleaning for removing contaminants from glass surfaces

Efficiency

One of the main benefits of laser cleaning is its efficiency. Unlike traditional cleaning methods that require manual labor and multiple steps, laser cleaning can remove contaminants from glass surfaces in a single pass. The high-energy laser beam vaporizes the contaminants, leaving behind a clean and residue-free surface. This not only saves time but also reduces the risk of damage to the glass.

Precision

Laser cleaning is also highly precise, allowing for targeted removal of contaminants without affecting the underlying glass surface. This is particularly important for delicate or intricate glass structures where traditional cleaning methods may cause damage. With laser cleaning, operators can control the intensity and focus of the laser beam to ensure that only the contaminants are removed, leaving the glass surface intact.

Eco-friendly

Another major benefit of laser cleaning is its eco-friendliness. Traditional cleaning methods often involve the use of harsh chemicals that can be harmful to the environment. Laser cleaning, on the other hand, is a chemical-free process that produces no waste or emissions. This makes it a sustainable and environmentally friendly option for cleaning glass surfaces.

Cost-effective

While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning is a more efficient and precise process, reducing the need for manual labor and expensive cleaning chemicals. This can result in lower maintenance costs and increased productivity for glass manufacturers.

Versatility

Laser cleaning is a versatile technology that can be used on a wide range of glass surfaces, including windows, mirrors, and glassware. It can remove a variety of contaminants, such as dirt, grease, and paint, without damaging the underlying glass. This makes it an ideal solution for cleaning glass surfaces in a variety of industries, from automotive to aerospace.

Conclusion

In conclusion, laser cleaning offers a number of benefits for removing contaminants from glass surfaces. From its efficiency and precision to its eco-friendliness and cost-effectiveness, laser cleaning is a superior alternative to traditional cleaning methods. As the glass industry continues to evolve, laser cleaning is likely to become an increasingly popular choice for maintaining clean and pristine glass surfaces.

Comparison of laser cleaning with traditional cleaning methods for glass surfaces

Traditional cleaning methods

1. Scrubbing: Scrubbing is a common method used to clean glass surfaces. It involves using a brush or sponge to remove dirt and grime from the surface. While scrubbing can be effective, it can also be time-consuming and labor-intensive.

2. Wiping: Wiping is another traditional cleaning method for glass surfaces. It involves using a cloth or paper towel to wipe away dirt and dust. While wiping is quick and easy, it may not be as effective at removing stubborn stains.

3. Chemical cleaning: Chemical cleaning involves using cleaning agents such as glass cleaners or ammonia to remove dirt and grime from glass surfaces. While chemical cleaning can be effective, it can also be harmful to the environment and pose health risks to those using the cleaning agents.

Laser cleaning

Laser cleaning is a non-contact cleaning method that uses a laser beam to remove dirt, grime, and other contaminants from glass surfaces. The laser beam is directed at the surface, where it vaporizes the contaminants without damaging the underlying material. Laser cleaning is fast, efficient, and environmentally friendly, making it an attractive alternative to traditional cleaning methods.

Comparison

1. Efficiency: Laser cleaning is more efficient than traditional cleaning methods, as it can remove dirt and grime more quickly and effectively.

2. Environmental impact: Laser cleaning is more environmentally friendly than traditional cleaning methods, as it does not require the use of harmful chemicals.

3. Cost: While laser cleaning may have a higher upfront cost than traditional cleaning methods, it can be more cost-effective in the long run due to its efficiency and reduced need for cleaning agents.

4. Safety: Laser cleaning is a safe and non-contact method that reduces the risk of injury to workers compared to traditional cleaning methods.

5. Precision: Laser cleaning allows for precise control over the cleaning process, making it ideal for delicate glass surfaces.

Overall, laser cleaning offers numerous advantages over traditional cleaning methods for glass surfaces. It is more efficient, environmentally friendly, and safe, making it a preferred choice for many industries. While traditional cleaning methods may still have their place, laser cleaning is a technology that is rapidly gaining popularity for its effectiveness and efficiency.

The science behind laser cleaning and how it works on glass surfaces

How Laser Cleaning Works

Laser cleaning works by using a high-powered laser beam to vaporize or ablate contaminants on the surface of a material. When the laser beam hits the surface, it creates a rapid and intense burst of energy that causes the contaminants to be removed. This process is highly precise and controlled, allowing for targeted cleaning without damaging the underlying material.

When it comes to glass surfaces, laser cleaning is particularly effective because glass is a transparent material that allows the laser beam to penetrate and interact with the contaminants on the surface. The laser energy is absorbed by the contaminants, causing them to be vaporized or ablated without affecting the glass itself.

The Science Behind Laser Cleaning

The science behind laser cleaning is based on the principles of laser physics and material interactions. When a laser beam is directed at a surface, it interacts with the material in several ways:

| Interaction | Description |

|---|---|

| Absorption | The laser energy is absorbed by the contaminants on the surface, causing them to heat up and be removed. |

| Reflection | If the laser energy is not absorbed by the material, it may be reflected off the surface without causing any cleaning effect. |

| Transmission | If the material is transparent, the laser energy may pass through it without interacting with the surface. |

By understanding these interactions, laser cleaning technicians can optimize the cleaning process for different materials and surfaces, including glass. The laser parameters, such as power, wavelength, and pulse duration, can be adjusted to achieve the desired cleaning results without damaging the underlying material.

Benefits of Laser Cleaning on Glass Surfaces

There are several benefits to using laser cleaning on glass surfaces:

| Benefit | Description |

|---|---|

| Precision | Laser cleaning is highly precise and controlled, allowing for targeted cleaning without damaging the glass surface. |

| No Chemicals | Laser cleaning does not require the use of chemicals or solvents, making it an environmentally friendly cleaning solution. |

| No Abrasives | Unlike traditional cleaning methods, laser cleaning does not use abrasives that can scratch or damage the glass surface. |

Overall, laser cleaning is a safe, efficient, and effective method for cleaning glass surfaces without causing damage. By understanding the science behind laser cleaning and how it works on glass surfaces, we can appreciate the benefits of this innovative technology in the cleaning industry.

Case studies of successful applications of laser cleaning on glass surfaces

Here are some :

1. Automotive industry 🚗

In the automotive industry, glass surfaces play a crucial role in ensuring driver visibility and safety. However, these surfaces can become contaminated with dirt, grease, and other residues, affecting visibility and aesthetics. Laser cleaning has been successfully used to remove contaminants from automotive glass surfaces, restoring clarity and functionality without damaging the glass. This has led to improved driver safety and enhanced vehicle aesthetics.

2. Aerospace industry ✈️

In the aerospace industry, glass surfaces are used in aircraft windows, cockpit displays, and other critical components. These surfaces are exposed to harsh environmental conditions and can become contaminated with dust, oil, and other debris. Laser cleaning has been effectively used to remove contaminants from aerospace glass surfaces, ensuring optimal performance and longevity. This has resulted in improved aircraft safety and reduced maintenance costs.

3. Electronics industry 📱

In the electronics industry, glass surfaces are used in displays, sensors, and other electronic components. These surfaces can become contaminated with fingerprints, dust, and other particles, affecting performance and aesthetics. Laser cleaning has been successfully applied to remove contaminants from electronic glass surfaces, ensuring optimal functionality and appearance. This has led to improved product quality and customer satisfaction.

Overall, laser cleaning has proven to be a highly effective and efficient method for cleaning glass surfaces in various industries. Its precision, speed, and environmental friendliness make it a preferred choice for cleaning delicate and sensitive surfaces. As technology continues to advance, laser cleaning is expected to play an increasingly important role in maintaining the cleanliness and functionality of glass surfaces in different applications.

Safety considerations when using laser cleaning for glass surfaces

Eye protection

One of the most important safety considerations when using laser cleaning for glass surfaces is eye protection. The intense light produced by the laser can cause serious damage to the eyes if proper precautions are not taken. It is essential to wear appropriate laser safety goggles that are designed to block the specific wavelength of light produced by the laser.

Fire hazards

Another important safety consideration when using laser cleaning for glass surfaces is the risk of fire. The intense heat produced by the laser can ignite flammable materials, so it is important to ensure that the work area is free of any combustible materials. It is also important to have fire extinguishing equipment on hand in case of an emergency.

Proper ventilation

When using laser cleaning for glass surfaces, it is important to ensure that the work area is properly ventilated. The process can produce fumes and vapors that may be harmful if inhaled, so it is important to have adequate ventilation to remove these contaminants from the air. It is also important to wear a respirator to protect against inhaling any harmful substances.

Training and supervision

It is essential that anyone using laser cleaning technology for glass surfaces receives proper training and supervision. This technology can be dangerous if not used correctly, so it is important to ensure that operators are fully trained in how to use the equipment safely. It is also important to have a supervisor present to oversee the process and ensure that all safety precautions are being followed.

Electrical safety

When using laser cleaning technology for glass surfaces, it is important to ensure that all electrical equipment is properly grounded and in good working condition. It is also important to follow all manufacturer’s guidelines for the safe use of the equipment and to regularly inspect it for any signs of damage or wear.

Conclusion

Overall, laser cleaning is a highly effective method for removing dirt and grime from glass surfaces. However, it is important to take certain safety precautions when using this technology to ensure the safety of both the operator and the surrounding environment. By following the safety considerations outlined above, you can ensure that your laser cleaning process is safe and effective.

- Laser cleaning for removing contaminants from glass surfaces - 3 July 2024

- 5 ways to optimize your website - 3 July 2024

- Business process automation in the edtech sector - 30 March 2024